聯系我們

-

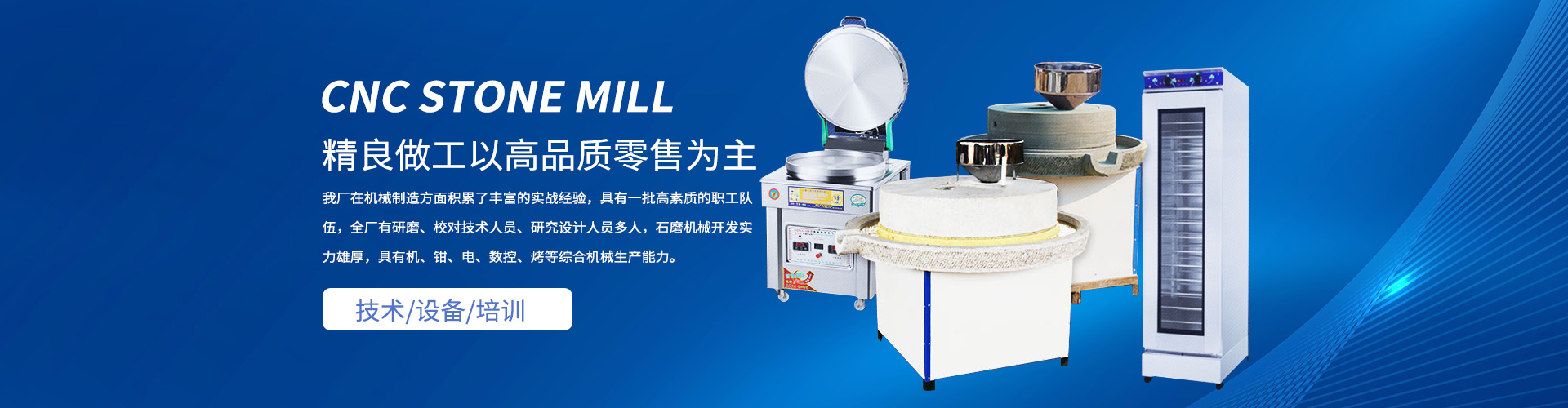

濟南中陽石磨電器有限公司

- 聯系:和經理

- 電話:17116125111

- 手機:17116125111

- 郵箱:3471464452@qq.com

- 網址:http://www.kongtiaochuzu.com

- 廠址:山東省濟南市章丘區相公莊鎮

芝麻醬石磨機會讓芝麻醬更加香醇!

來源:http://www.kongtiaochuzu.com/發布時間:2022-01-14

芝麻醬的生產工藝較為簡單,將洗凈后的芝麻瀝干經過高溫加熱焙炒,焙炒芝 The production process of sesame paste is relatively

芝麻醬的生產工藝較為簡單,將洗凈后的芝麻瀝干經過高溫加熱焙炒,焙炒芝

The production process of sesame paste is relatively simple. Drain the washed sesame, heat it at high temperature and bake it

麻被研磨后,得到醬體是一種多相分散體系。主要成分為油脂和固形物,水分含量極少量,形成油包水(W/O)懸浮液。芝麻研磨破碎后呈漿狀,醬體由油脂組成的液相和各種顆粒物質組成的固相形成的懸浮液,各種顆粒物質主要為變性蛋白質、碳水化合物、纖維素和灰分和其他結合物。

After the hemp is ground, the sauce is a heterogeneous dispersion system. The main components are grease and solids, and the moisture content is very small, forming a water in oil (w / O) suspension. Sesame is slurry after grinding and crushing. The sauce body is a suspension formed by liquid phase composed of oil and solid phase composed of various particulate substances. Various particulate substances are mainly denatured protein, carbohydrate, cellulose, ash and other conjugates.

在芝麻醬的生產工藝流程中原料篩選清洗、高溫烘炒和研磨為三個關鍵點,必須在這三點上進行嚴格把關。

In the production process of sesame paste, raw material screening and cleaning, high-temperature baking and grinding are three key points, which must be strictly controlled.

,原料的篩選可直接影響到芝麻醬的品質和,去除被微生物污染的霉變芝麻,反復清洗帶有重金屬或有農藥殘留的芝麻,避免將有毒物質直接帶入芝麻醬中產品食品問題。

Firstly, the screening of raw materials can directly affect the quality and safety of sesame paste. Remove the moldy sesame contaminated by microorganisms, and repeatedly clean the sesame with heavy metals or pesticide residues, so as to avoid bringing toxic substances directly into sesame paste and product food safety problems.

芝麻清洗完成后要經歷一個吸水的過程,一般25~40分鐘左右,有利于美拉德反應的生成條件。

After sesame cleaning, it needs to go through a water absorption process, generally about 25 ~ 40 minutes, which is conducive to the formation conditions of Maillard reaction.

其次,芝麻的特有香氣形成關鍵在于烘炒過程,因此烘炒是芝麻醬工藝流程中極為重要的一步,一般烘炒選用平底炒鍋和轉筒烘炒機,而烘炒的溫度和時間就是這一過程的重要因素。一般焙炒溫度在 180℃-200℃之間,烘炒時間為 10-20min 以獲得芝麻油所需焙炒芝麻;烘炒溫度在 150℃-175℃之間,烘炒時間為 15-20min 以獲得芝麻醬所需焙炒芝麻,而焙炒程度的判定為主觀判定,炒后芝麻呈棕色,用手指一捏即變粉末狀。若溫度過高或者焙炒時間過長都會導致芝麻焦苦,不僅對芝麻產品的風味和口感有所影響,也在焙炒過程中產生對人體有危害的苯并芘物質。

Secondly, the key to the formation of sesame's unique aroma lies in the drying and frying process. Therefore, drying and frying is a very important step in the sesame paste process. Generally, flat frying pan and rotary drum frying machine are selected for drying and frying, and the temperature and time of drying and frying are important factors in this process. Generally, the baking temperature is 180 ℃ - 200 ℃ and the baking time is 10-20min to obtain the roasted sesame seeds required by sesame oil; The baking temperature is between 150 ℃ - 175 ℃, and the baking time is 15-20min to obtain the baked sesame seeds required for sesame paste. The judgment of baking degree is subjective. The fried sesame seeds are brown and become powder as soon as they are pinched with your fingers. If the temperature is too high or the baking time is too long, the sesame will be scorched and bitter, which will not only affect the flavor and taste of sesame products, but also produce benzopyrene substances harmful to human body in the baking process.

有條件的工廠,一般會先做烘干處理,然后再進一步炒制,這種工藝生產的熟芝麻,香味更加濃郁,芝麻顆粒受熱更均勻。

Conditional factories usually do drying treatment first and then further frying. The cooked sesame produced by this process has stronger flavor and more uniform heating of sesame particles.

不同的焙炒工藝處理芝麻對芝麻油的風味及品質的影響。目前常用的有燃氣滾筒炒鍋、電磁炒鍋、微波炒鍋等,不同的炒鍋炒制的工藝參數不同,焙炒方

Effects of different roasting processes on the flavor and quality of sesame oil. At present, gas drum frying pan, electromagnetic frying pan and microwave frying pan are commonly used. The frying process parameters of different frying pans are different

式、溫度和時間對芝麻油的風味都有著顯著性的影響。

Formula, temperature and time had significant effects on the flavor of sesame oil.

芝麻的研磨過程是芝麻醬狀形成的關鍵步驟之一。

The grinding process of sesame is one of the key steps in the formation of sesame paste.

將烘炒芝麻用石磨或者膠體磨研磨成漿狀,細度一般在 88-100um 之間更適,但不大于280um。研磨過程中醬體的溫度會隨著研磨次數的增多和研磨時間的延長而升高,而高溫則會使得油脂氧化,影響芝麻醬的品質和營養價值,因此芝麻醬研磨過程中一般會使用二次研磨法。

Grind the roasted sesame into slurry with stone mill or colloidal mill. The fineness is generally between 88-100um, but not more than 280um. During the grinding process, the temperature of the sauce body will increase with the increase of grinding times and grinding time, while the high temperature will oxidize the oil and affect the quality and nutritional value of sesame paste. Therefore, the secondary grinding method is generally used in the grinding process of sesame paste.

可將小麥胚芽、花生仁和芝麻按 9:70:20 的配比比例混合制成多維麥胚花生芝麻醬。在芝麻的預處理中,芝麻的烘炒是通過電炒鍋實現,控溫在120℃烘炒 10min 外皮的顏色微黃。待炒好后冷卻的芝麻通過電動石磨粗磨后經膠體磨細化處理,即二次研磨法。粗磨料溫在50℃左右,細磨控溫在 70℃-75℃之間。

Multi dimensional wheat germ peanut sesame paste can be prepared by mixing wheat germ, peanut kernel and sesame in the ratio of 9:70:20. In the pretreatment of sesame, the baking and frying of sesame is realized by electric frying pan. The temperature is controlled at 120 ℃ for 10 minutes until the color of the skin is yellowish. After being fried, the cooled sesame is roughly ground by an electric stone mill and then refined by a colloidal mill, that is, the secondary grinding method. The temperature of coarse abrasive is about 50 ℃, and the temperature of fine grinding is between 70 ℃ and 75 ℃.

相關新聞

- 提高香油石磨機的出油率有方法2022-05-30

- 石磨豆漿機特點優點相關內容介紹2022-05-29

- 面粉石磨機保證加工制品的純度方法2022-05-29

- 芝麻醬石磨機的四步使用方法2022-05-27

相關產品